Trident Desiccant Air Dryers

Trident Desiccant Air Dryers

- Designed For – 1S0:7183-1986 (E)

- Dryer Quality Class – 1S0:8573-1:2010 (E) class 2

- Pre-Filter Quality Class – 1S0:8573-1:2010 (E) class 1

- Consistent Dew Point performance

- Noise Level <70 dBA © Pressure Drop < 0.3 kg/em*(g)

- CE &e(@) Marked* @ Aluminum Construction

- Free From Corrosion & Scale Formation at Inner and Outer

sides - Uses High Crush Strength Adsorbent Materials

Application

- Painting And Powder Coating

- Machine Tool

- Packaging

- Auto Garagel Textile & Garment

- Industry (pressurizes its underground cables to repel moisture and avoid shorts)

- Feed air for Zeolite type Oxygen and Nitrogen generators

- Pneumatic control systems

- Truck and Train Air brake systems.

Market Acceptance

- Excellent Performance

- High Reliability

- Require Less Service Time

- Reasonable Cost

- Low moving components

- Low Maintenance

- Safe Operation

- Global Support

Principle of Operation

- Drying Cycle: Moist air from the compressor is sent through the coalescing filter. Here water & oil coalesces and purge through the auto drain valve. The relatively clean air with water vapour passing through the aluminum drying tower filled with desiccant gets completely dried (up to -400C PDP) and then passes through a built-in filter (25 microns). The desiccant fines from the towers are completely removed and clean dry air is let out through the outlet port for use.

- Regeneration Cycle: During the regeneration cycle, the sudden depressurization brings out water molecules strapped in the Desiccant pores to the surface of the beads. A small portion of dry compressed air from the drying tower then passes over the desiccant through the regeneration orifice built in the Top Block. This results in complete regeneration of the Desiccant.

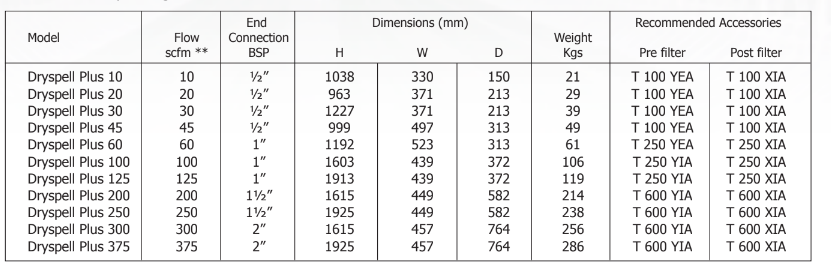

Specifications

- Maximum Operating Pressure: 16 kg/cm2 (g)

Air Inlet Temperature: 380C Max

Operating Pressure: 7 kg/cm2 (g)

Pre-Filter Rating: 0.01 Micron

Cycle Time: 4 Minutes

Operating Voltage: 100-240 VAC 50/60 Hz 1 Ph

Outlet Conditions: Dry air at -400C PDP*

Purge Loss: 15±1%

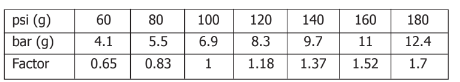

Inlet Pressure Correction Factor

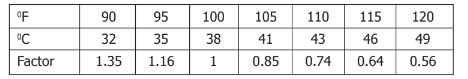

Temperature Correction Factor